Why choosing the right Aluminum Foundry ensures superior casting quality

Wiki Article

The Importance of Aluminum Casting in High-Quality Production Techniques

Aluminum spreading has become a foundation in high-grade manufacturing techniques. Its light-weight residential or commercial properties and phenomenal stamina make it a preferred option for numerous markets. Makers gain from its layout versatility and marginal waste generation. As the need for advanced products grows, understanding the subtleties of aluminum spreading becomes necessary. This expedition discloses not just its advantages but additionally the evolving technologies that shape its future in manufacturing. What exists ahead for this innovative procedure?

The Benefits of Aluminum Spreading

Different casting approaches exist, light weight aluminum spreading stands out due to its various benefits. Among the primary advantages is its lightweight nature, which substantially decreases transport prices and energy consumption in applications. Aluminum also shows exceptional deterioration resistance, making it optimal for lasting elements in diverse settings. The spreading procedure permits detailed layouts, making it possible for makers to produce complicated forms with high precision and minimal waste. Additionally, aluminum has superior thermal and electric conductivity, making it ideal for a series of commercial applications. The high strength-to-weight proportion enhances the architectural honesty of actors products, giving durability without the included mass. Furthermore, aluminum casting can be adjusted to various methods, such as sand spreading or pass away casting, which widens its applicability across industries. On the whole, these advantages setting aluminum spreading as a favored option in modern-day production, contributing to effectiveness and sustainability.Secret Applications of Light Weight Aluminum Spreading

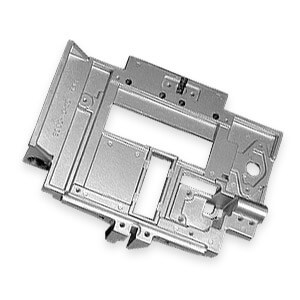

Light weight aluminum casting discovers considerable applications across different industries because of its helpful buildings. In the automotive field, it is extensively utilized for making engine blocks, transmission cases, and wheels, promoting light-weight styles that enhance fuel effectiveness. The aerospace industry likewise benefits from light weight aluminum spreading, where components such as braces and real estates are created to fulfill strict weight and toughness needs.Additionally, the electric market uses aluminum casting for creating real estates and heat sinks, which are essential for effective thermal administration in electronic devices. Aluminum Foundry. The construction market makes use of aluminum spreadings for architectural components, window frames, and components, adding to both looks and toughness

Finally, the consumer goods field integrates light weight aluminum spreading in things like pots and pans and showing off equipment, leveraging the product's strength and corrosion resistance. On the whole, the adaptability of aluminum spreading makes it a vital process in meeting varied production requires across numerous fields.

The Process of Light Weight Aluminum Spreading

Casting aluminum entails several distinct actions that transform basic materials into finished components. The procedure starts with melting light weight aluminum in a heater, getting to temperature levels around 660 degrees Celsius. As soon as melted, the liquid aluminum is put into a mold and mildew, which takes the shape of the desired component. Different mold and mildew kinds, consisting of sand, long-term, and investment mold and mildews, are used depending on the application.

After pouring, the aluminum cools and solidifies, forming a harsh spreading. This casting undergoes a series of completing processes, such as machining, to accomplish specific dimensions and surface high quality. Quality assurance actions are executed throughout to ensure the honesty and stamina of the end product. As soon as all processes are total, the completed light weight aluminum components are prepared for various applications, showcasing the adaptability and effectiveness of aluminum casting in manufacturing techniques. Each action is critical in attaining top notch results, making this process crucial in manufacturing sectors.

Technologies in Light Weight Aluminum Casting Innovation

Recent developments in aluminum casting modern technology have changed manufacturing procedures considerably. Developments such as innovative casting techniques, integration of clever manufacturing, and sustainability techniques are reshaping the industry. These developments not only improve effectiveness yet also address environmental problems, leading the way for a much more sustainable future in aluminum spreading.Advanced Casting Techniques

As manufacturers look for higher effectiveness and sustainability in production, cutting-edge developments in aluminum spreading technology have actually emerged to fulfill these demands. Advanced casting techniques, such as die casting, financial investment spreading, and sand spreading, have been refined to enhance precision and lower waste. Die casting allows for faster manufacturing rates and tighter resistances, making it optimal for high-volume things. Financial investment casting, recognized for its capability to generate intricate geometries, allows elaborate layouts with superior surface finishes. On the other hand, sand spreading continues to be popular for its adaptability and cost-effectiveness, specifically in low-volume applications. These methods not only improve the top quality of light weight aluminum components however likewise add to lowered energy intake, aligning with sector objectives for lasting methods in making procedures.Smart Manufacturing Combination

Just how can wise production integration change light weight aluminum spreading modern technology? By incorporating advanced innovations such as the Net of Points (IoT), fabricated intelligence (AI), and data analytics, smart manufacturing improves effectiveness and precision in aluminum casting procedures. Real-time tracking of equipment and manufacturing lines enables for prompt adjustments, minimizing waste and downtime. Anticipating upkeep powered by AI minimizes devices failings, making certain consistent high quality. Additionally, data analytics can enhance casting layouts and criteria, leading to far better material usage and decreased cycle times. These developments assist in seamless interaction in between operators and devices, fostering a more agile production environment. Overall, clever production integration significantly boosts the abilities of aluminum spreading, advertising higher top quality outcomes and more receptive production techniques.Sustainability Innovations

While the light weight aluminum spreading market deals with enhancing stress to take on lasting methods, developments are emerging that considerably reduce its environmental influence. Advanced recycling techniques currently make it possible for makers to utilize up to 95% recycled light weight aluminum, substantially decreasing power usage and waste generation. Additionally, the assimilation of low-emission innovations, such as electrical melting heating systems, minimizes greenhouse gas exhausts related to typical casting techniques. Additionally, the advancement of eco-friendly finishes and binders changes damaging chemicals, boosting office safety and decreasing environmental air pollution. These advancements not just straighten with international sustainability objectives however also enhance the overall efficiency and top quality of light weight aluminum items. As the sector develops, these improvements will play an important duty in promoting an extra lasting future for light weight aluminum spreading.Comparing Aluminum Casting With Other Techniques

In contrasting aluminum casting with various other making approaches, numerous critical elements arise. Price toughness, effectiveness and toughness, and layout flexibility function as vital metrics for analysis (Aluminum Casting Company). Examining these aspects can offer insights right into the benefits and limitations of light weight aluminum casting in various manufacturing contextsExpense Efficiency Analysis

Price effectiveness remains a vital factor to consider in producing processes, particularly when evaluating aluminum spreading versus alternative methods. Aluminum casting usually provides a lower first financial investment contrasted to methods such as steel forging or machining, which call for even more intricate and costly tools. In addition, aluminum's lightweight nature can lower transport costs and power usage during manufacturing. The capacity to develop complicated shapes with very little waste further boosts its cost-effectiveness, as much less material is discarded during the manufacturing procedure. Light weight aluminum casting typically permits for quicker production cycles, leading to reduced labor expenses and faster turnaround times. To sum up, when comparing expense efficiency, aluminum spreading frequently becomes a favorable choice, supplying manufacturers economic advantages together with high-quality output.Stamina and Sturdiness

Stamina and longevity are essential elements when reviewing manufacturing methods, particularly in the context of aluminum spreading. Compared to other approaches such as plastic injection molding and steel construction, light weight aluminum spreading provides unique advantages. The inherent properties of aluminum, integrated with the spreading procedure, result in lightweight yet robust components that can withstand significant tension and environmental elements. Unlike plastics, which may deteriorate with time, light weight aluminum keeps its integrity and performance under heats and stress. Furthermore, while steel elements can be heavier and prone to corrosion, aluminum resists rusting, enhancing longevity. This combination of strength and toughness makes aluminum casting a recommended selection for sectors calling for dependable performance popular applications, such as auto and aerospace markets.Layout Adaptability Comparison

The Future of Aluminum Spreading in Production

Just how will developments in innovation form the future of aluminum spreading in manufacturing? The integration of automation and fabricated knowledge is anticipated to reinvent aluminum casting procedures. These modern technologies can improve precision and effectiveness, lowering waste and production prices. Furthermore, the development of 3D printing methods enables quick prototyping and personalized layouts, allowing makers to react swiftly to market demands.Sustainability is additionally an important emphasis, with advancements intended at decreasing energy intake and lessening ecological impact. Techniques such as die casting and financial investment spreading are advancing to incorporate recycled aluminum, promoting a circular economic situation.

Furthermore, innovations in products scientific research may result in the growth of lighter, more powerful light weight aluminum alloys that can increase the applications of light weight aluminum spreading throughout various industries. Generally, the future of light weight aluminum spreading in production will likely be defined by raised performance, flexibility, and sustainability, positioning it as a necessary element of modern manufacturing strategies.

Often Asked Concerns

How Does Aluminum Casting Impact Environmental Sustainability?

Aluminum casting favorably affects ecological sustainability by promoting recycling, decreasing power intake compared to various other steels, and lessening waste. Its website lightweight properties additionally cause lower exhausts throughout transportation, sustaining greener methods in various sectors.What Are the Expense Ramifications of Light Weight Aluminum Spreading?

Light weight aluminum casting often requires higher first prices because of product and processing expenditures. Nevertheless, its resilience and light-weight buildings can yield lasting cost savings by lowering upkeep and transportation expenses, eventually stabilizing the financial effects for manufacturers.Can Light Weight Aluminum Spreading Be Recycled Properly?

Light weight aluminum casting can be recycled efficiently, as the material preserves its residential properties throughout the reusing procedure. This permits for the manufacturing of premium parts while lessening waste and reducing energy consumption connected with new aluminum manufacturing.What Precaution Are Needed During Aluminum Spreading?

Precaution during aluminum spreading include using personal safety tools like handwear covers and safety glasses, making certain correct air flow, maintaining tools, and adhering to methods for handling liquified steel to avoid burns, breathing threats, and various other possible crashes.

Just How Does Light Weight Aluminum Casting Affect Product Design Versatility?

Aluminum casting enhances product design adaptability by making it possible for lightweight structures and intricate shapes. This technique permits developers to discover cutting-edge setups, leading to functional applications throughout different industries while keeping stamina and toughness in the last products.Light weight aluminum casting can be adjusted to various techniques, such as sand spreading or pass away casting, which widens its applicability throughout markets. When all processes are total, the finished light weight aluminum elements are all set for different applications, showcasing the convenience and performance of aluminum casting in production strategies. As makers look for better performance and sustainability in manufacturing, ingenious improvements in aluminum spreading technology have arised to fulfill these needs. Unlike plastic shot molding, which may require extensive tooling modifications for style adjustments, light weight aluminum spreading can fit alterations a lot more easily during the production cycle. Developments in materials scientific research may lead to the growth of lighter, more powerful aluminum alloys that might broaden the applications of light weight aluminum spreading across numerous markets.

Report this wiki page